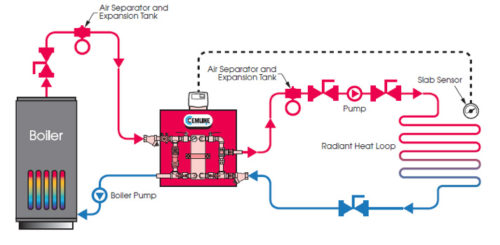

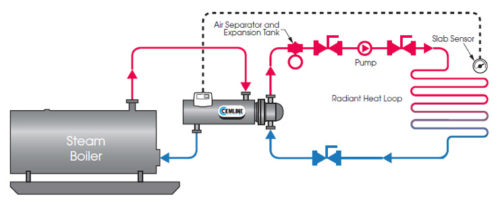

Steam / Boiler Water / High Temperature Hot Water / Chilled Water

- Building Heat, Process Heat, Swimming Pool Heater, Snow Melt, Cooling Applications

- Steam, Boiler Water, High Temperature Hot Water, Chilled Water

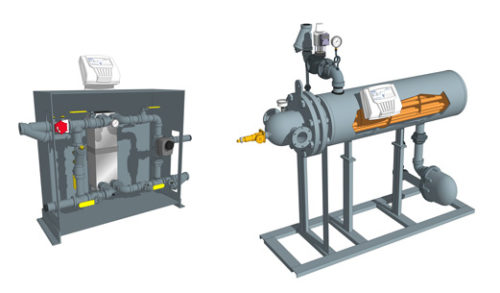

- Shell & Tube and Plate Heat Exchangers

The Cemline Heat Transfer Package (HTP Series) is a heat exchange package designed to provide heat transfer between energy source (steam, boiler water, HTHW or chilled water) and the process liquid (water, pool water, thermal oil, or glycol blend, etc.). This package is provided with a heat exchanger, controls, and accessories allowing easy installation. When using boiler water as the energy source the brazed plate heat exchanger is supplied. A brazed plate heat exchanger can provide a lower approach temperature than a shell and tube heat exchanger while helping to improve the efficiency of today’s condensing boiler(s). The CEM-TROL® II electronic controller and 2 or 3-way control valve delivers steady output temperature to the process fluid in a boiler water application. A shell and tube heat exchanger is an industry standard when using steam as the energy source and is supplied with a steam application. The CEM-TROL® II controller and steam control valve and condensate traps provide delivers steady output temperature to the process fluid in a steam application. Factory packaging keeps contractor installation time to a minimum the only connections of steam/condensate, boiler water or HTHW, heating fluid, and electric.